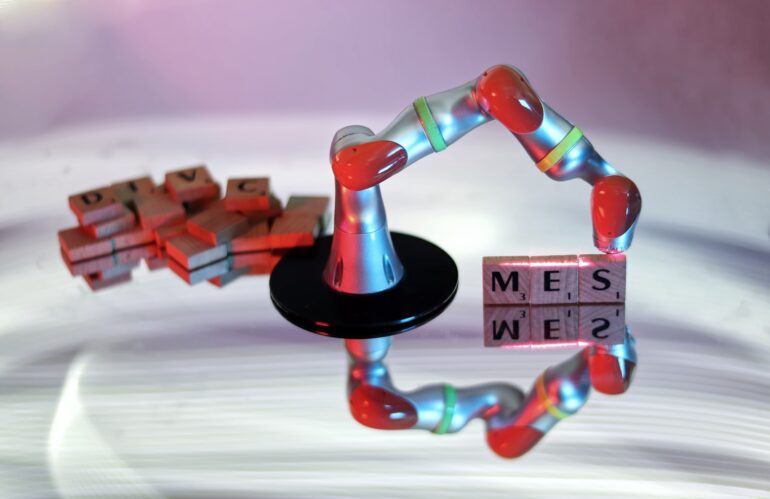

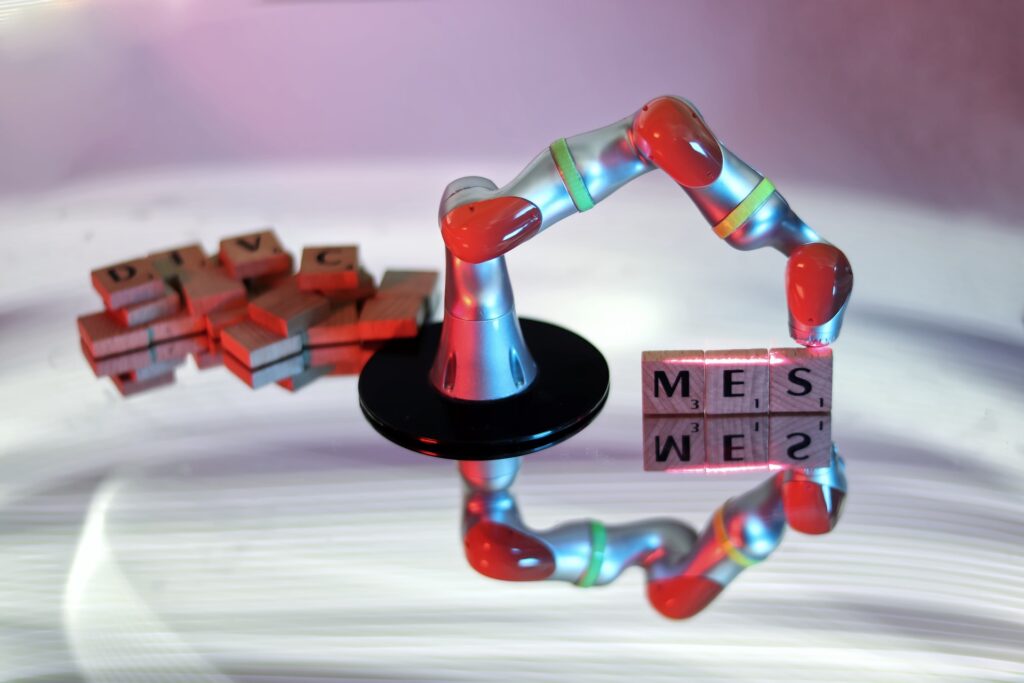

Manufacturing Execution Systems (MES) are software applications that collect and analyze data from the manufacturing floor to help improve efficiency, quality, and compliance. MES is typically used in industries such as pharmaceuticals, food and beverage, automotive, and electronics to increase production efficiency, reduce errors, and improve quality control.

The latest trends in MES technology include:

- Cloud-based MES: Cloud-based MES systems offer a number of advantages over traditional on-premises systems, including scalability, flexibility, and cost-effectiveness.

- Mobile MES: Mobile MES systems allow users to access MES data and functionality from anywhere, on any device. This can be especially beneficial for manufacturing personnel who need to access MES data while they are on the shop floor.

- Big data analytics: Big data analytics can be used to gain insights into manufacturing data that would not be possible with traditional methods. This can help manufacturers to identify areas for improvement, such as bottlenecks in production or quality issues.

- Artificial intelligence (AI): AI is being used in MES systems to automate tasks, such as quality control and scheduling. This can help to improve efficiency and productivity.

- The Industrial Internet of Things (IIoT): The IIoT is the network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, actuators, and connectivity which enables these things to connect and exchange data. IIoT is being used in MES systems to collect data from manufacturing equipment and sensors. This data can be used to improve efficiency, quality, and compliance.

These are just a few to name it. As MES systems continue to evolve, it will play an increasingly important role in helping manufacturers to improve their operations.

Here are some of the features & benefits of using a Manufacturing Execution System (MES):

- Production monitoring: MES provides real-time monitoring of the production process, including machine performance, production output, and quality control. This allows manufacturers to identify problems as they occur and take corrective action immediately.

- Resource management: MES enables manufacturers to manage resources such as materials, labor, and equipment in real-time. This includes tracking inventory levels, scheduling personnel, and managing maintenance schedules for equipment.

- Quality control: MES provides real-time quality control monitoring, enabling manufacturers to track quality metrics, identify defects, and take corrective action immediately. This helps to ensure that products meet the required quality standards.

- Traceability: MES provides end-to-end traceability, enabling manufacturers to track materials, products, and processes from start to finish. This is particularly important in industries such as pharmaceuticals, where traceability is essential for compliance with regulatory requirements.

- Performance analysis: MES provides detailed performance analysis, enabling manufacturers to identify areas for improvement and optimize their production processes. This includes identifying bottlenecks, analyzing production data, and providing real-time feedback to operators.

- Improved efficiency: MES systems can help to improve efficiency by providing real-time data and insights into the manufacturing process. This data can be used to identify bottlenecks and areas for improvement.

If you are looking for ways to improve the efficiency, quality, and compliance of your manufacturing operations, we offer custom MES solutions tailored to match the needs of our clients. Contact us for a free consultation.